Introduction: Understanding the Concept of a Factory Audit

A factory audit is a comprehensive assessment conducted to evaluate the quality, efficiency, and compliance of a manufacturing facility. It involves an independent inspection and analysis of various aspects of the factory's operations, processes, and systems, aiming to ensure that the facility meets the required standards and regulations.

The Importance of Factory Audits

Factory audits play a crucial role in ensuring product quality, worker safety, and ethical manufacturing practices. By conducting regular audits, companies can identify potential risks, address non-compliance issues, and improve overall operational efficiency.

Types of Factory Audits

There are several types of factory audits, each serving a specific purpose:

1. Quality Audit

A quality audit focuses on assessing the factory's quality management system, including the implementation of quality control procedures, adherence to product specifications, and documentation of quality records.

2. Social Compliance Audit

A social compliance audit evaluates the factory's compliance with labor laws, health and safety regulations, child labor policies, working hours, and employee welfare initiatives. It ensures that workers are treated fairly and that ethical standards are upheld.

3. Environmental Audit

An environmental audit examines the factory's environmental management practices, waste management systems, pollution control measures, and compliance with environmental regulations. It ensures that the manufacturing processes are environmentally sustainable.

4. Security Audit

A security audit focuses on assessing the factory's security measures, including access control, surveillance systems, and protection against theft, vandalism, and unauthorized entry. It helps safeguard the factory's assets and protects against potential risks.

5. Supplier Audit

A supplier audit evaluates the capabilities, reliability, and compliance of a factory's suppliers. It ensures that suppliers meet the required quality standards and have robust systems in place to deliver the necessary materials or components.

The Factory Audit Process

The factory audit process typically involves the following steps:

1. Pre-audit Preparation

Prior to the audit, the auditor gathers relevant information about the factory, such as its location, size, production capacity, and specific areas to be assessed. They also review any previous audit reports and checklists.

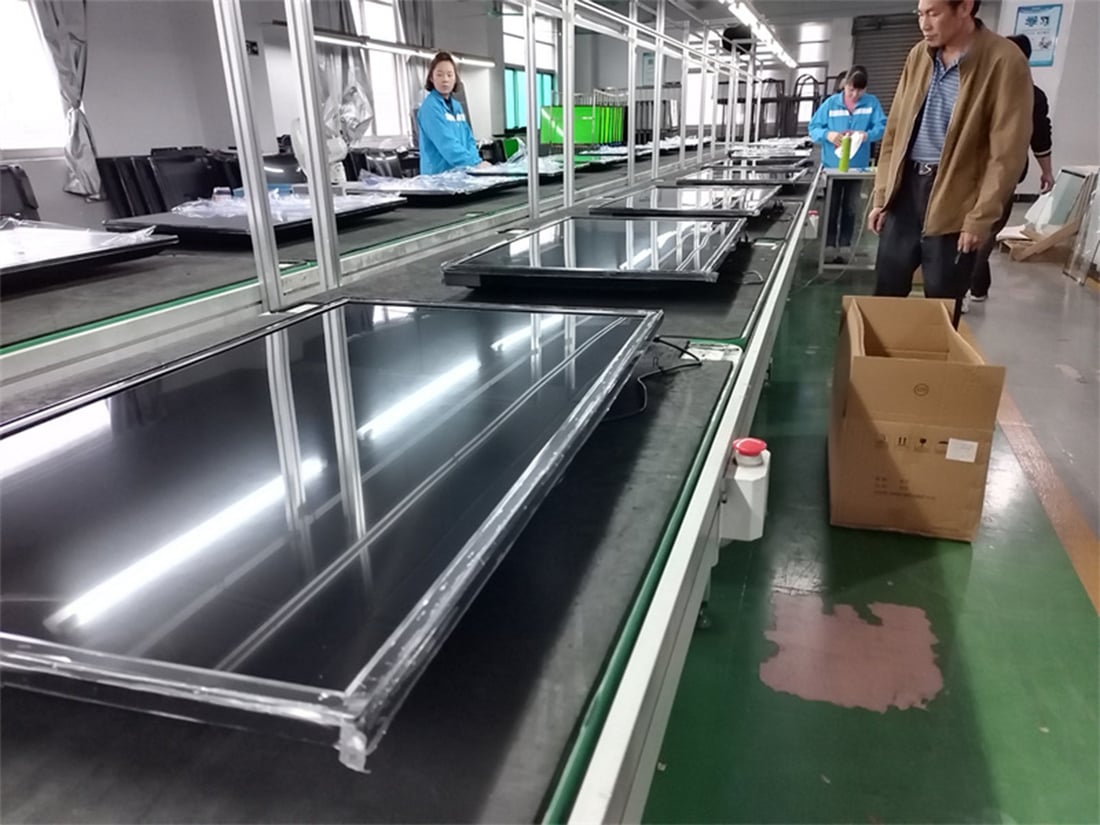

2. On-site Inspection

During the on-site inspection, the auditor examines various aspects of the factory, including production facilities, equipment, quality control processes, worker conditions, and documentation. They may conduct interviews with management and workers to gather additional information.

3. Data Analysis

After the on-site inspection, the auditor analyzes the collected data, compares it against the required standards and regulations, and identifies any areas of non-compliance or improvement.

4. Audit Report

Based on the findings, the auditor prepares a detailed audit report, highlighting the strengths, weaknesses, and areas for improvement. The report includes recommendations for corrective actions and timelines for implementation.

5. Follow-up Actions

Once the audit report is shared with the factory management, they initiate the necessary actions to address the identified non-compliance issues and make the required improvements. A follow-up audit may be conducted to ensure that the corrective actions have been implemented effectively.

Benefits of Factory Audits

Factory audits offer several benefits to both manufacturers and consumers:

1. Ensuring Product Quality

By conducting regular factory audits, manufacturers can identify quality issues early on and implement necessary improvements to ensure that their products meet the required quality standards.

2. Mitigating Risks

Factory audits help identify potential risks and hazards in the manufacturing processes, enabling proactive measures to mitigate them. This includes addressing safety concerns, preventing environmental pollution, and avoiding legal and reputational risks.

3. Compliance with Regulations

Factory audits ensure that manufacturing facilities comply with local and international regulations, standards, and certifications. This helps build trust among consumers and demonstrates a commitment to ethical and responsible manufacturing practices.

4. Enhancing Efficiency

Through the identification of operational inefficiencies and process bottlenecks, factory audits help manufacturers streamline their operations, reduce waste, and improve overall productivity.

5. Protecting Workers' Rights

Social compliance audits play a vital role in ensuring fair treatment of workers, compliance with labor laws, and the elimination of exploitative practices such as child labor or forced labor.

Conclusion

A factory audit is a crucial tool for manufacturers to assess and improve the quality, compliance, and sustainability of their operations. By conducting regular audits, companies can enhance efficiency, mitigate risks, and ensure ethical and responsible manufacturing practices.