When it comes to product quality, hardlines inspection plays a crucial role in ensuring that the product meets the required standards. The term hardlines refer to products that are made of hard materials like plastic, metal, or glass. These products have to go through various inspection procedures to ensure their functionality, safety, and overall quality. In this article, we will discuss the importance of hardlines inspection in ensuring the product's reliability and safety.

Functional Inspection

Functional inspection is an essential aspect of hardlines inspection. It ensures that the product performs its intended function correctly. For example, in the case of a kitchen appliance, functional inspection ensures that the appliance functions correctly, as indicated in the manual. Every component of the appliance must work smoothly together. Any malfunction can create undesirable consequences that may result in damage to the appliance or harm to the user.

Product Safety Inspection

While functional inspection focuses on ensuring products work correctly, safety inspection is concerned with ensuring the product is not harmful to the user. Safety inspection entails assessing the product's safety features, such as the handling of sharp edges, temperature control, or power cords. In the case of a toy, safety inspection ensures that there are no small parts that can be swallowed or sharp edges that could injure a child.

Quality Inspection

Quality inspection is all about making sure the product meets the desired quality standards. Quality inspection for hardlines entails an assessment of physical parameters like weight, dimensions, and material composition, amongst others. Ensuring that specific quality standards are met ensures satisfaction to the buyer, creating trust and confidence in the product.

Compliance Inspection

Compliance inspection checks the product's compliance to local, national, or international regulatory requirements. Regulatory requirements differ from country to country, and products that don't meet these requirements are not fit for sale. For instance, compliance inspection ensures that a toy does not contain any prohibited substances or that electrical products comply with safety regulations before being sold in a particular state.

Batch Inspection

Batch inspection is done during the product's manufacturing process, ensuring that every batch is uniform and meets the required quality standards. Any subpar batch is eliminated to avoid defective products reaching the market. The inspection process ensures that the manufacturer makes the necessary corrections before continuing with production, saving them time and resources.

Spot-check Inspection

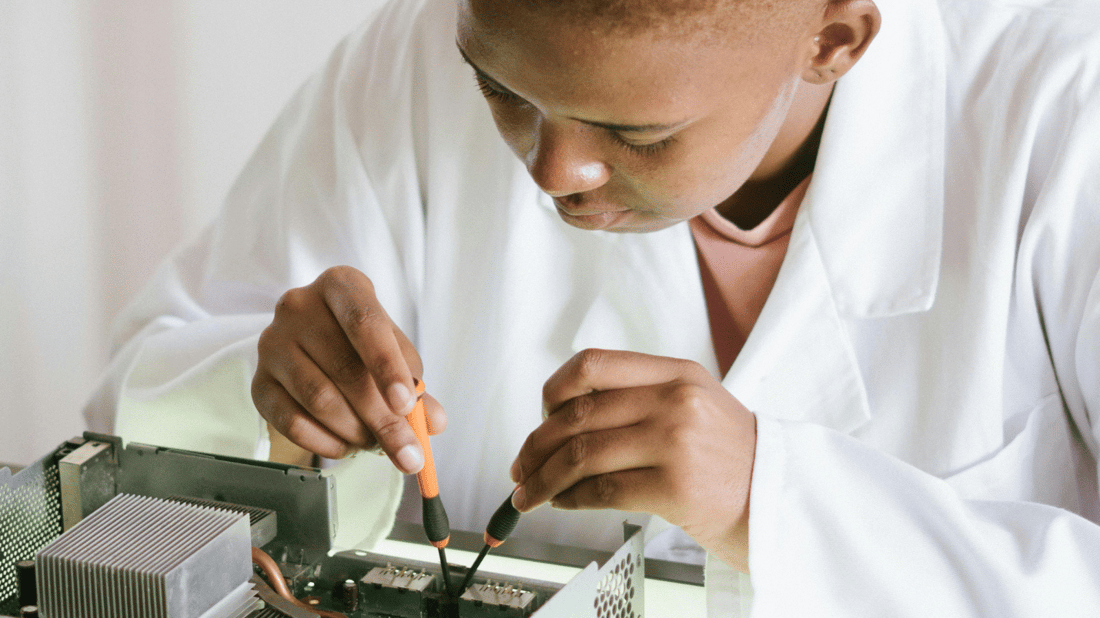

Spot-check inspection is a process of randomly selecting products from a specific batch to assess their quality. Spot-check inspections ensure that products are manufactured evenly, and batches with non-compliant products are caught before the products are released into the market, as illustrated in Figure 1 below.

Third-party Inspection

Third-party inspection is an independent inspection carried out by an external entity other than the manufacturer or those involved in the product's sale. Third-party inspection provides an unbiased assessment of the product quality and ensures that every product is tested and verified to meet the required standards.

Benefits of Hardlines Inspection

Ensuring product quality through hardlines inspection offers several benefits. Some of these are:

- Quality products that meet the buyer's expectations

- Avoidance of defective products reaching the market

- Increased customer confidence and brand loyalty

- Reduced liability claims

- Improved safety standards

The Bottom Line

Hardlines inspection is crucial to ensure that products meet the required standards. Quality, safety, and functionality assessments ensure that every product is desirable, meets the desired standards, is safe for use, and performs as required.

Hardlines inspection, functional inspection, product safety, quality inspection, compliance inspection, batch inspection, spot-check inspection, third-party inspection, benefits of hardlines inspection

Why Hardlines Inspection is Necessary for Product Quality?

Hardlines inspection plays a crucial role in ensuring that the product meets the required standards. Functional inspection, product safety inspection, quality inspection, compliance inspection, batch inspection, spot-check inspection, third-party inspection, and benefits of hardlines inspection.

Quote Inquiry

If you have any questions, please let us know asap!