The Basics of Hardlines Inspection

Hardlines inspection is a vital process employed to ensure that products are safe, reliable, and of high quality. This type of examination involves the thorough analysis of hardware, machinery, and equipment that are used in a wide range of industries, including consumer products, automotive, construction, and medical devices. It is typically conducted by trained professionals who have a keen eye for detail and can recognize potential risks and hazards that may pose a threat to user safety and product reliability.

The Importance of Hardlines Inspection

The hardlines inspection process helps businesses to conform to safety standards set by regulatory agencies, including the United States Consumer Product Safety Commission (CPSC). In addition, hardlines inspection helps to ensure that products meet the necessary quality standards, which can enhance customer satisfaction and brand reputation.

Key Components of Hardlines Inspection

The hardlines inspection process has various key components, including visual examination, testing, sampling, and analysis, and document review. Visual examination involves inspecting products for visual defects and damage, while testing involves performing functional tests on equipment and machinery. Sampling and analysis involve taking a sample of a product and analyzing it to ensure that it meets established standards. Finally, document review involves analyzing certificates that prove compliance with regulatory requirements, such as safety and quality standards.

The Benefits of Regular Hardlines Inspection

Regular hardlines inspection has numerous benefits. It helps to identify potential quality and safety issues before they become major problems, prevents product recalls, and reduces the risk of product liability lawsuits. Regular inspection also assists businesses in maintaining high-quality products that meet regulatory requirements and consumer expectations.

How Hardlines Inspection is Conducted

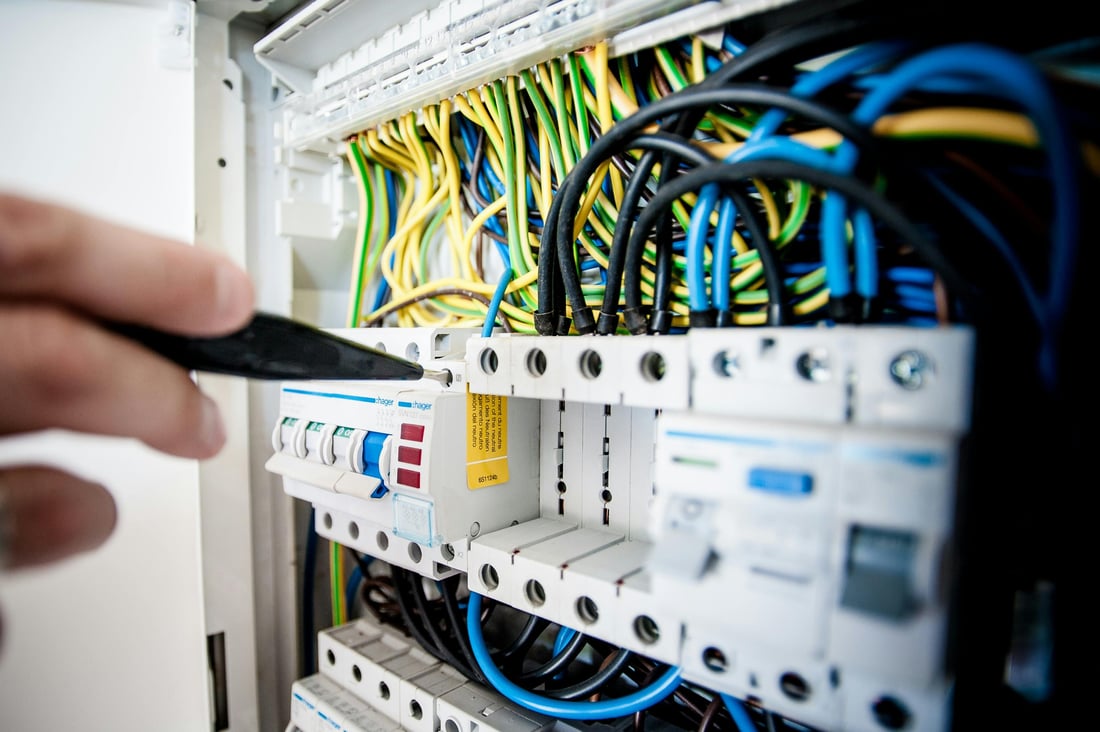

Hardlines inspection is conducted by trained professionals who have expertise in specific industries and understand the regulatory requirements of their respective fields. Inspection may be conducted on-site and/or at the manufacturing facility. The inspector will use various tools and techniques to evaluate the hardware, machinery, and equipment being inspected, including measuring tools, magnifying devices, and specialized testing equipment.

Examples of Products that Require Hardlines Inspection

Hardlines inspection is conducted on a wide range of products, including but not limited to:

- Outdoor and sporting equipment such as bicycles and helmets

- Home appliances such as refrigerators and washing machines

- Children's toys and furniture

- Medical and dental equipment such as surgical instruments and dental drills

- Automotive parts and engines

The Role of Hardlines Inspection in Product Development

Hardlines inspection plays an essential role in the product development process. Inspection can identify design and manufacturing issues early on, which can result in cost savings and time efficiencies. By identifying and correcting issues early in the process, businesses can avoid costly product recalls and improve the overall quality of their products.

Training and Certification for Hardlines Inspectors

Hardlines inspectors must undergo training and certification in specific areas of inspection, including but not limited to:

- Visual examination

- Product testing

- Sampling and analysis

- Regulatory requirements

Professional organizations such as the International Association of Certified Home Inspectors (InterNACHI) offer training programs and certification for hardlines inspectors.

Choosing a Hardlines Inspection Provider

When choosing a hardlines inspection provider, it is important to select a company with a proven track record of professionalism, expertise, and experience. Look for a provider that offers comprehensive inspection services, has certified inspectors, and has experience working in your industry. You should also ensure that the company adheres to regulatory requirements and can provide detailed inspection reports.

Conclusion

Hardlines inspection is a critical process that ensures safety, reliability, and quality in the products we use every day. By regularly inspecting products, businesses can avoid product recalls, maintain their reputation, and improve customer satisfaction. It is important to choose a qualified and experienced inspection provider to ensure that your products meet regulatory requirements and customer expectations.