How to Perform a Factory Audit: A Comprehensive Guide

When it comes to manufacturing, ensuring quality and compliance is of utmost importance. One way to achieve this is through a factory audit. A factory audit involves a systematic examination of a manufacturing facility to assess its overall performance, quality control processes, and adherence to industry standards. In this article, we will explore the various aspects of conducting a factory audit, from preparation to execution and reporting.

1. Understanding the Purpose of a Factory Audit

A factory audit serves multiple purposes, all aimed at evaluating the capabilities and quality management systems of a manufacturing facility. It allows businesses to assess if a potential supplier meets their requirements, ensures compliance with industry regulations, and identifies areas for improvement. By conducting a factory audit, companies can mitigate risks, maintain product consistency, and safeguard their reputation.

2. Preparing for a Factory Audit

Prior to conducting a factory audit, thorough preparation is essential. Start by defining the scope and objectives of the audit. Identify the key areas to be assessed, such as production processes, quality control measures, health and safety protocols, and environmental practices. Develop an audit checklist that aligns with industry standards and your specific requirements.

3. Selecting the Right Audit Team

A successful factory audit requires a competent and experienced audit team. Choose individuals with relevant expertise in manufacturing processes, quality management, occupational health and safety, and environmental compliance. The team should possess strong analytical skills, attention to detail, and effective communication abilities.

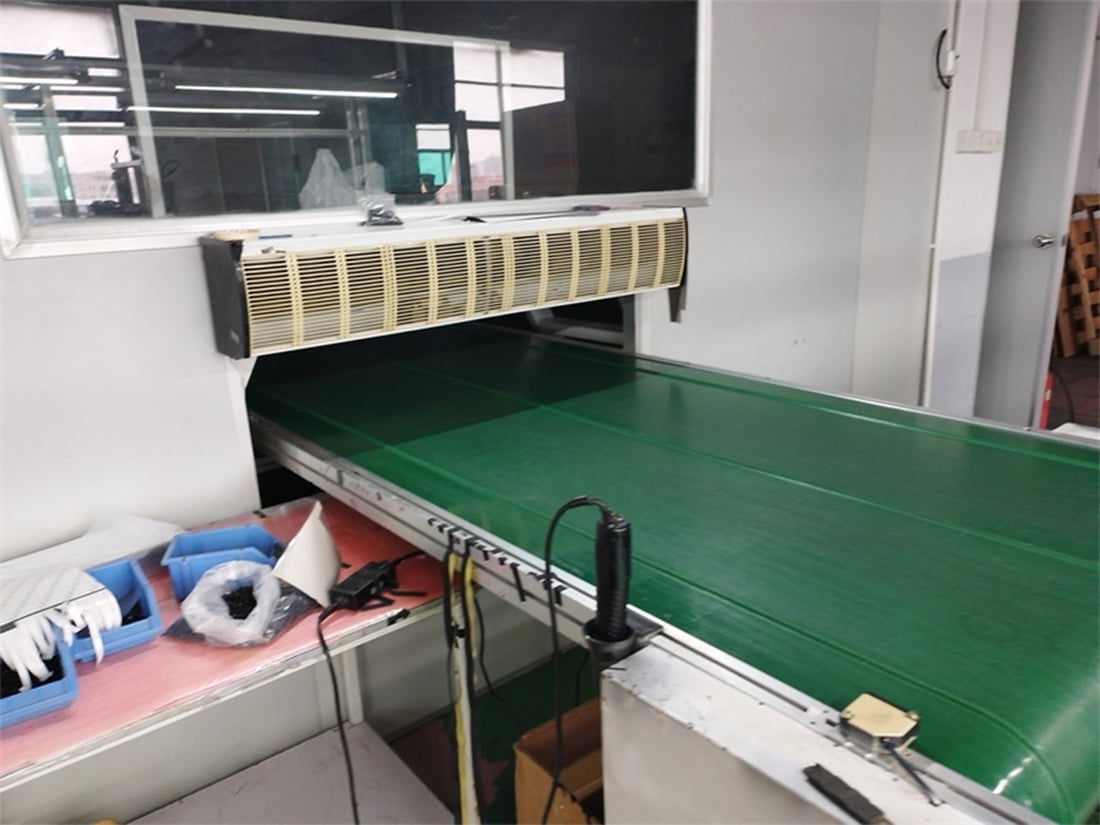

4. Conducting the On-Site Audit

Once on-site, the audit team should begin by conducting an opening meeting with the factory management. This meeting serves to establish rapport, clarify the audit objectives, and outline the audit process. The team should then proceed with a thorough examination of the factory's facilities, equipment, and processes. They should review documentation, interview key personnel, and observe operations to assess compliance and identify any gaps or non-conformities.

5. Assessing Quality Control Measures

A critical aspect of a factory audit is evaluating the effectiveness of quality control measures. The audit team should review the factory's quality management system, including procedures for incoming raw materials inspection, in-process quality checks, and final product testing. They should also assess the factory's corrective and preventive actions, as well as its record-keeping practices.

6. Evaluating Health and Safety Protocols

Ensuring a safe working environment is paramount in any factory audit. The audit team should evaluate the factory's compliance with local health and safety regulations, including the presence of safety policies, procedures, and training programs. They should inspect the factory floor for potential hazards, assess the availability and proper use of personal protective equipment, and review accident/incident records.

7. Reviewing Environmental Practices

In today's environmentally conscious world, evaluating a factory's environmental practices is crucial. The audit team should assess the factory's compliance with environmental regulations, such as waste management, air emissions, and water treatment. They should review documentation related to environmental permits, perform site inspections, and verify the implementation of environmental management systems.

8. Reporting and Follow-Up

After completing the on-site audit, the audit team should compile a detailed report highlighting their findings, observations, and recommendations. The report should be comprehensive, objective, and concise. It should include a summary of the audit scope, methodology, and key findings. Additionally, the report should identify areas for improvement and suggest corrective actions. Timely follow-up is essential to ensure that identified non-conformities are addressed effectively.

9. Benefits of Regular Factory Audits

Regular factory audits offer numerous benefits to both manufacturers and their clients. They help manufacturers identify areas for improvement, enhance product quality, and streamline processes. For clients, factory audits provide assurance of product consistency, compliance with standards, and ethical manufacturing practices. Additionally, regular audits foster transparency, trust, and long-term partnerships between manufacturers and clients.

10. Conclusion

A factory audit is a vital tool for ensuring quality, compliance, and continuous improvement in manufacturing. By carefully planning and executing a factory audit, businesses can mitigate risks, identify areas for enhancement, and maintain a competitive edge in today's global marketplace.