Introduction

It is important for businesses to conduct supplier audits in order to ensure that their suppliers adhere to the established quality criteria. In a supplier audit, a representative from the company inspects the supplier's facilities, work processes, and documentation to determine if they meet the company’s standards. This article will provide a comprehensive guide on How to Conduct a Supplier Audit.

1. Prepare for the Audit

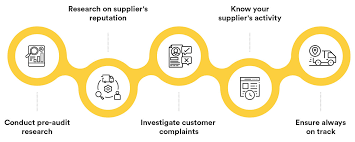

Before conducting the audit, establish the audit criteria and objectives. The criteria should be based on the supplier's performance and potential risks that may affect quality. Decide whether to conduct an on-site or remote audit, and select the auditors with appropriate experience. Notify the supplier in advance, and request all relevant documentation.

2. Start with Documentation

Review the supplier’s documentation to ensure it is complete and up-to-date. Documentation may include certifications, licenses, quality manuals, and training records. Verify the accuracy of the documents, and check if they comply with the relevant standards and regulations.

3. Evaluate Facilities and Equipment

Inspect the supplier’s facilities to assess if they are suitable for the intended purposes. Check if the equipment is well-maintained and calibrated, and if it meets the required standards. Identify any potential hazards, and evaluate any corrective actions taken to mitigate them. Ensure that the facilities and equipment comply with safety regulations.

4. Employee Training and Competence

Evaluate the employees' qualifications, training, and competence. Verify if the training records are complete and if the training content complies with the relevant standards. Assess whether the employees have sufficient knowledge and skills to perform their duties competently.

5. Examine their Quality Management System

Review the supplier’s quality management system (QMS) to evaluate if it is effective in ensuring the quality of products or services. Verify if it complies with the relevant quality standards, and evaluate its documentation, implementation, and effectiveness. Identify any non-conformities, and evaluate if they have been addressed properly.

6. Assess their Records Management

Review the supplier’s record-keeping procedures to evaluate if they are adequate and effective. Verify if they comply with relevant standards and regulations, and evaluate their accuracy, completeness, and confidentiality. Check if they are well-organized and easily accessible.

7. Evaluate their Supply Chain Management

Assess the supplier’s supply chain management procedures to determine how they manage their own suppliers. Verify if they have procedures to evaluate and approve their suppliers, and whether they monitor their suppliers’ performance. Evaluate whether their suppliers are capable of meeting the required quality standards.

8. Identify Non-conformities and Opportunities for Improvement

Identify any non-conformities or non-compliances with the established criteria during the audit. This may include issues that impact the quality of their products or services. Provide recommendations for corrective actions and opportunities for improvement based on the identified issues. Work collaboratively with the supplier to mitigate any issues discovered to ensure a better relationship.

9. Maintain Communication with the Supplier

Maintain open and clear communication with the supplier throughout the audit process. Discuss the audit findings and recommendations with them, and provide them with an opportunity to provide feedback. Establish a review period for their corrective actions to ensure that the issues have been resolved.

10. Follow-up Audit

Perform a follow-up audit to determine if the corrective actions have been implemented effectively. During the follow-up audit, use the same criteria and objectives as the initial audit. Ensure that the supplier has taken steps to mitigate any non-conformities identified during the initial audit.