Introduction

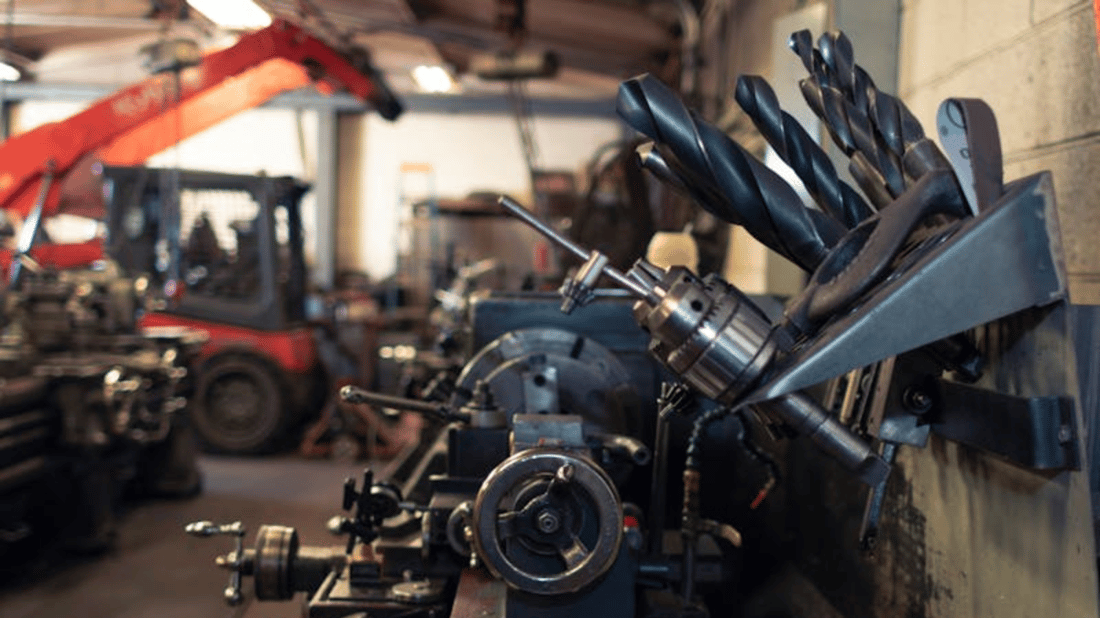

Ground drill bits are essential tools when it comes to digging holes. They are designed to tackle the toughest soils, but they are not invincible. If you want to ensure your drill bits perform optimally, it's essential to regularly inspect and maintain them. Let's take a closer look at what Ground Drill Bit Inspections entail.

1. The Importance of Ground Drill Bit Inspection

Inspecting ground drill bits is crucial for two reasons. Firstly, regular inspections allow you to detect and resolve any issues before they become severe and cause damage to the bit or the drill. Secondly, inspections can increase the lifespan of your bits, saving you time and money in the long run.

2. When to Inspect Your Ground Drill Bit

It's vital to inspect your ground drill bits before and after every use. Examining them before use ensures they are in good shape and free from any damages or cracks that could cause further damage during use. Post-use inspections, on the other hand, help you identify wear and tear, clean the bit, and detect any signs of corrosion or damage.

3. Preparing for Inspection

Before inspecting your ground drill bit, it's vital to clean it thoroughly. Remove any dust, dirt, or debris that could obscure areas where signs of damage might be visible. Use a soft brush or a damp cloth to clean any excess material from the bit.

4. Visual Inspection

During visual inspection, you are looking for signs of wear and/or damage. Check for any cracks, chips, nicks, or dings in the bit. Also, look for signs of rust or corrosion, which can weaken the bit's strength and structural integrity. Don't forget to check the cutting edge for chipping or dulling.

5. Measuring the Bit

Part of ground drill bit inspection involves measuring the bit's dimensions using a vernier caliper or a micrometer. Take note of the diameter, total length, and the cutting edge's length. When measuring the diameter, measure both the narrowest and widest points to determine if there's any tapering.

6. Checking the Threads

If the ground drill bit has threads, it's essential to check their condition. Check for any loose threads, cracks, or stripped threads, which could cause damage to the drill or even become a safety hazard.

7. Inspect the Shank

The bit's shank is just as important as the cutting edge. Inspect it for any damage such as cracks, bends, or chips, paying extra attention to the neck area, where most of the stress is concentrated.

8. Metal Fatigue

Apart from visible signs of damage, ground drill bit inspection should also focus on detecting signs of metal fatigue. Metal fatigue can cause the bit to break or become brittle, reducing its strength and lifespan.

9. Knowing When to Retire a Bit

If your ground drill bit has exceeded a certain level of wear and tear, it's vital to retire it, even if it looks safe to use. Retiring a bit that is past its prime is crucial for safety reasons.

10. Conclusion

In summary, ground drill bit inspection is vital to ensure your bits remain in good condition and perform optimally. By regularly inspecting the bit, you'll be able to detect any signs of damage, wear and tear, or corrosion and take appropriate action to mitigate further damage. Remember always to retire bits past their prime to avoid safety hazards.