Glassware Inspection Method: Ensuring Quality and Safety

Glassware plays an integral role in various industries, including pharmaceuticals, laboratories, and food manufacturing. It is crucial to ensure the quality and safety of glassware, which requires an effective inspection method. In this article, we will discuss the different aspects of the glassware inspection method.

Why is Glassware Inspection Important?

Glass is a fragile material that can easily break or crack, especially under extreme conditions. In industries that use glassware, such as laboratories, the consequences of a broken or defective glassware can be catastrophic. Glassware inspection is, therefore, essential to ensure the safety of personnel and the quality of products.

Types of Glassware Inspection Methods

There are different methods for inspecting glassware, including visual inspection, non-destructive testing, and destructive testing. The choice of method depends on the type of glassware, its purpose, and the extent of damage or defects.

Visual Inspection

The most common method of inspecting glassware is visual inspection. This method involves examining the glassware for any visible defects, such as cracks, chips, or scratches. Visual inspection is simple and cost-effective, but it may not detect defects that are not visible to the naked eye.

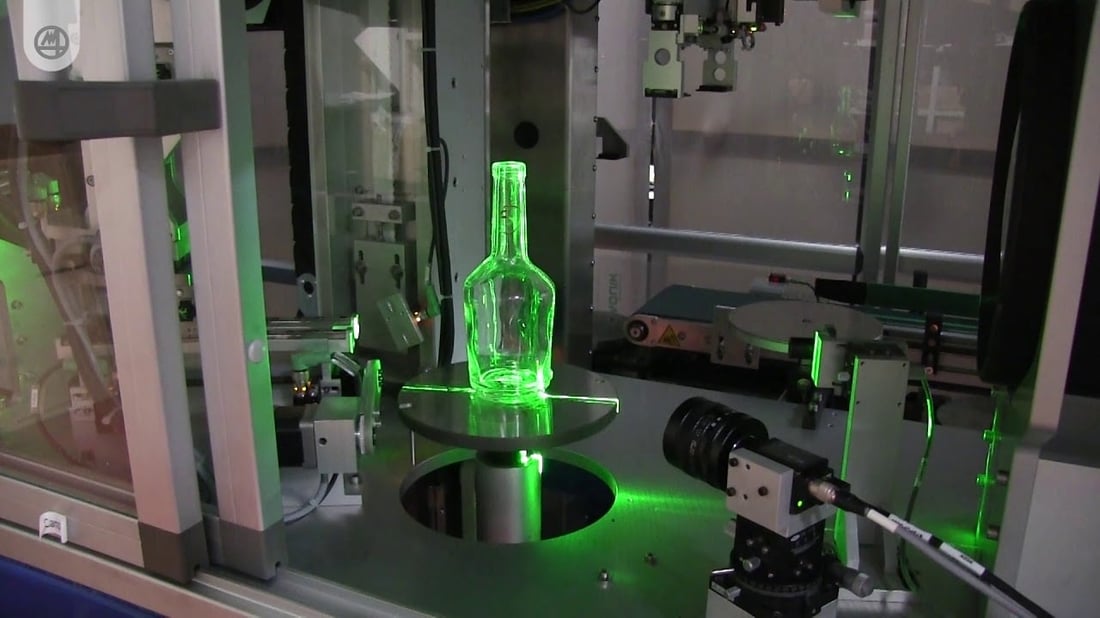

Non-Destructive Testing

Non-destructive testing (NDT) is a method of testing the integrity of glassware without causing damage to it. Common NDT techniques used for glassware inspection include ultrasonic testing, X-ray inspection, and liquid penetrant testing. These techniques can detect defects that are not visible to the naked eye and are, therefore, more accurate than visual inspection.

Destructive Testing

Destructive testing involves testing the glassware to failure, which means it cannot be used afterward. This method is often used for testing the strength of glassware or identifying defects that are difficult to detect using other methods.

Frequency of Glassware Inspection

The frequency of glassware inspection depends on the type of glassware and its purpose. For example, glassware used in a laboratory should be inspected before and after each use to ensure it is clean and free of defects. In contrast, glassware used in food packaging may only need to be inspected periodically to ensure it meets regulatory requirements.

Documentation and Recordkeeping

All glassware inspections should be properly documented and recorded. Documentation should include the date of inspection, the method used, the condition of the glassware, and any actions taken. Recordkeeping is crucial for traceability and for identifying recurring issues that need to be addressed.

Training and Competency

Glassware inspection should be performed by trained and competent personnel who have a good understanding of the inspection methods, procedures, and equipment. Proper training and competency assessments are necessary to ensure that the inspections are accurate and reliable.

Conclusion

Glassware inspection is a critical element in ensuring the quality and safety of products in various industries. The choice of inspection method depends on the type of glassware, its purpose, and the extent of defects. Proper documentation, recordkeeping, training, and competency assessments are essential for effective glassware inspection.