1. The Importance of Electronic Product Testing

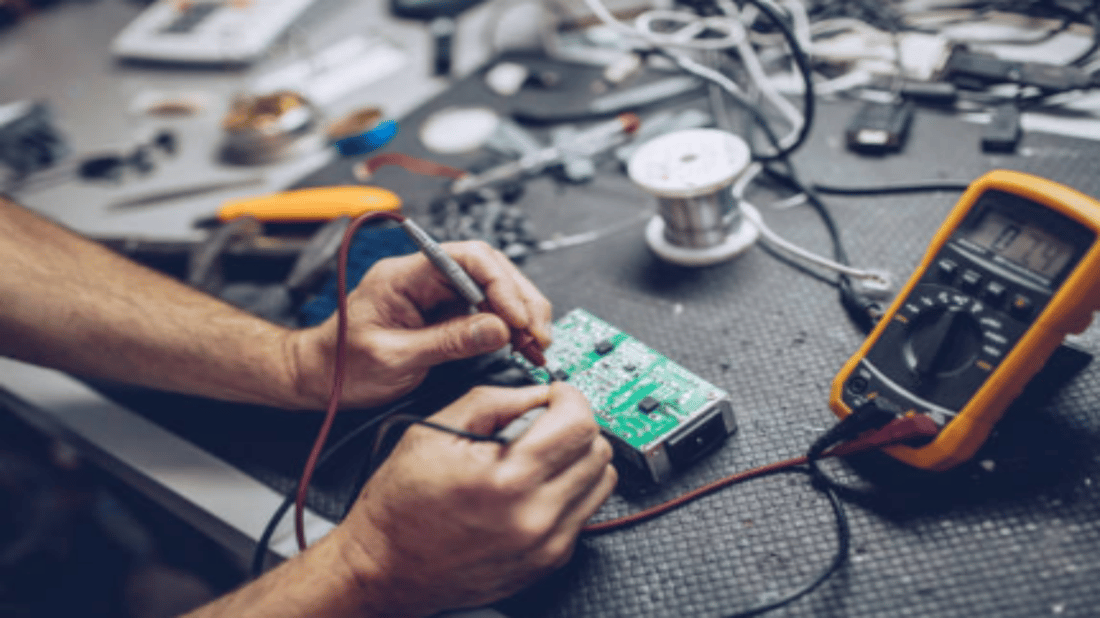

electronic product testing plays a crucial role in ensuring the quality and reliability of consumer electronics. With the rapid advancement of technology, electronic devices have become an integral part of our daily lives. From smartphones and laptops to home appliances and wearable devices, the market is flooded with a wide range of electronic products. However, without proper testing, these products may fail to meet the necessary standards, leading to potential safety hazards and performance issues.

2. Ensuring Safety Compliance through Testing

One of the primary reasons for electronic product testing is to ensure safety compliance. Electrical devices, if not properly tested, can pose serious risks such as electric shocks, fires, and explosions. Testing helps identify any potential safety hazards, such as faulty wiring, insulation problems, or inadequate protection against electrical surges. By subjecting electronic products to rigorous testing procedures, manufacturers can ensure that their products meet the required safety standards and regulations.

3. Testing for Performance and Functionality

Electronic product testing also focuses on evaluating the performance and functionality of devices. Consumers expect their electronic products to perform optimally under various conditions. Whether it's a smartphone with fast processing speeds or a washing machine with efficient water consumption, thorough testing helps identify any performance issues or functional limitations. By conducting tests that simulate real-world usage scenarios, manufacturers can fine-tune their products to deliver superior performance.

4. Reliability Testing: Ensuring Longevity

Reliability testing is an essential aspect of electronic product testing. Consumers invest their hard-earned money in electronic devices with the expectation that they will last for a reasonable period. Reliability tests are conducted to assess the durability and longevity of products, ensuring they can withstand normal wear and tear. These tests involve subjecting devices to extreme temperature variations, humidity, vibration, and other environmental factors to simulate real-life conditions. By identifying weak points and potential failures, manufacturers can improve the overall reliability of their products.

5. Environmental Testing: Adapting to Various Conditions

With the increasing demand for electronic products in various industries, it is crucial to test their performance in different environments. Environmental testing evaluates how electronic devices perform under extreme temperatures, humidity levels, and atmospheric pressures. This testing ensures that products can withstand harsh conditions and operate reliably in diverse settings. From military-grade equipment to outdoor consumer electronics, environmental testing helps manufacturers design products that can adapt to challenging environments.

6. Electromagnetic Compatibility Testing

Electronic devices often operate in close proximity to each other, and electromagnetic interference can disrupt their performance. Electromagnetic compatibility (EMC) testing is conducted to ensure that electronic products can coexist and function properly without causing interference. This testing involves evaluating devices for their emission and susceptibility to electromagnetic radiation. By complying with EMC standards, manufacturers can ensure that their products won't interfere with other electronic devices or be affected by external electromagnetic sources.

7. Regulatory Compliance and Certification

Electronic product testing is closely linked to regulatory compliance and certification. Different countries and regions have specific regulations and standards that electronic devices must meet before they can be sold in the market. By conducting comprehensive testing, manufacturers can ensure that their products comply with these regulations. Certification from recognized testing authorities adds credibility to the product and instills confidence in consumers. Compliance with regulatory requirements also helps manufacturers avoid legal issues and penalties.

8. Testing for Quality Assurance

Quality assurance is a critical aspect of electronic product testing. By subjecting products to rigorous testing procedures, manufacturers can identify any manufacturing defects or design flaws. Quality assurance testing includes visual inspections, functional tests, and performance evaluations to ensure that each unit meets the specified quality standards. By maintaining consistent quality across their product range, manufacturers can build a reputation for reliability and customer satisfaction.

9. Testing for Product Improvement and Innovation

Electronic product testing not only focuses on ensuring quality and compliance but also serves as a driving force for innovation and improvement. By analyzing test results, manufacturers can identify areas for improvement in their products. This feedback loop enables them to refine their designs, enhance performance, and introduce new features based on customer needs and preferences. Testing also helps manufacturers stay ahead of the competition by identifying emerging trends and technological advancements.

10. The Future of Electronic Product Testing

As technology continues to evolve at a rapid pace, electronic product testing will play an even more significant role in ensuring the quality, safety, and reliability of consumer electronics. With the advent of new technologies such as artificial intelligence, Internet of Things, and 5G, testing procedures will need to adapt to cater to the unique challenges posed by these advancements. Manufacturers and testing laboratories will need to invest in state-of-the-art equipment and expertise to keep up with the growing complexity of electronic devices.