The Differences Between Brass and Copper

Brass and copper are two common metals used in various industrial applications. Although they may look similar, they have different properties and are better suited for different projects. Brass is an alloy made of copper and zinc while copper is a pure metal. Below are the key differences between brass vs copper:

- Brass is more malleable and ductile than copper, making it easier to shape into different forms.

- Copper has better thermal conductivity than brass, making it ideal for use in heat transfer applications.

- Brass has higher corrosion resistance than copper, particularly in marine environments, due to the added zinc content.

- Copper has a higher electrical conductivity than brass, making it the preferred material for electrical wiring.

- Brass has a lower melting point than pure copper, making it easier to cast and machine.

The Applications of Brass vs Copper

Due to their unique properties, brass and copper are suitable for various applications.

Brass Applications

Brass is commonly used in:

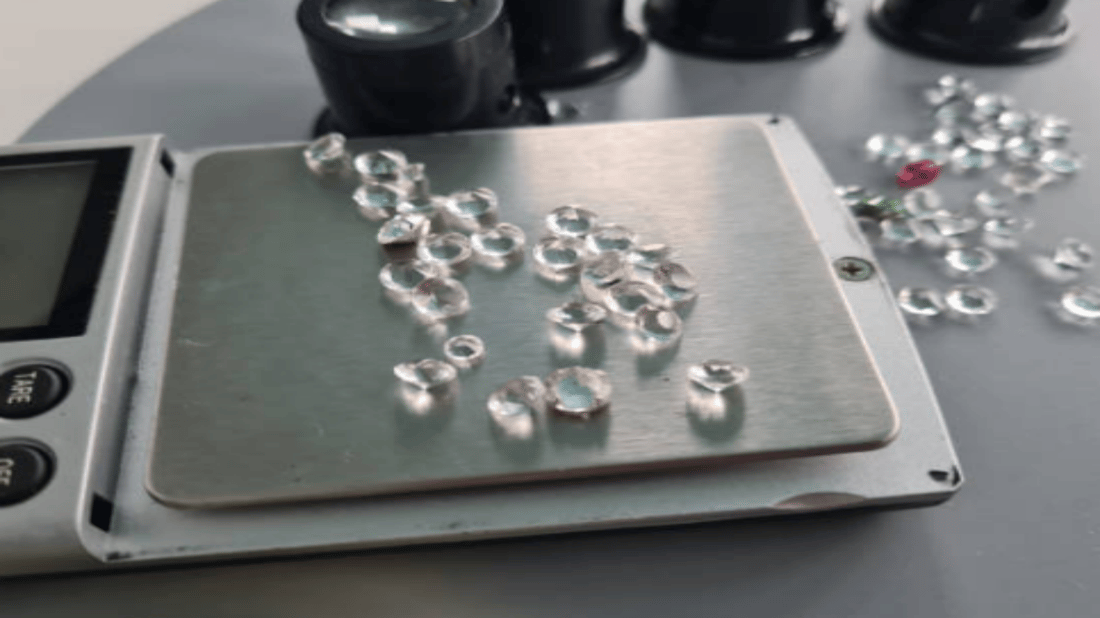

- Jewelry making

- Plumbing fixtures

- Automotive parts

- Brass musical instruments

- Screws and bolts

Copper Applications

Copper is commonly used in:

- Electrical wiring

- Heat exchangers

- Plumbing pipes

- Roofing materials

- Musical instruments like trumpet and saxophone

The Pros and Cons of Brass vs Copper

Brass Pros

- Durable and long-lasting

- Easy to shape and machine

- Highly resistant to corrosion

- Comes in many different finishes

Brass Cons

- Not suitable for high-temperature applications

- May cause allergic reactions in some individuals

- More expensive than other base metals

Copper Pros

- Excellent electrical conductivity

- Excellent thermal conductivity

- Flexible and can be easily bent

- Resistant to bacteria and fungi growth

Copper Cons

- Prone to corrosion

- Not as strong as other metals

- May oxidize and turn green over time

Conclusion: Brass vs Copper, Which Is Better?

Choosing between brass vs copper ultimately comes down to the specific project requirements. Copper is preferred for electrical and heat transfer applications while brass is better suited for corrosion resistance and aesthetic appeal. Both are great choices for various industrial purposes, but brass may be the preferable option when there is a need for both beauty and functionality.