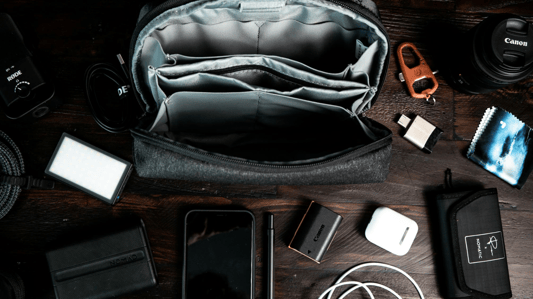

Mobile Accessories Inspection: Everything You Need to KnowMobile accessories are essential for many people as they complement smartphones, tablets, and other mobile devices. Before the accessories reach the consumers' hands, they go through various producers, manufacturers, and distributors. As a result, it's essential to conduct mobile accessories inspection to ensure the products are safe, reliable, and meet the required standards.What is Mobile Accessories Inspection?Mobile accessories inspection is a quality control process that involves examining mobile accessories to ensure they meet specific standards and requirements. The inspection process assesses various criteria, including the accessories' physical appearance, functions, and safety features. The process ensures that the consumer gets quality and reliable products while adhering to the given regulatory requirements.Why is Mobile Accessories Inspection Important?Mobile accessories inspection is essential because it ensures that consumers get quality, reliable, and safe products. With the various counterfeit products in the market, inspection is critical in helping to identify such products. Additionally, inspection also ensures that the accessories meet the given regulatory requirements, protecting public health and the environment.The Benefits of Mobile Accessories InspectionMobile accessories inspection comes with numerous benefits, including:Ensuring quality and reliable productsPreventing the distribution of counterfeit productsProtecting public health and the environment by ensuring adherence to regulatory requirementsEnsuring customer satisfaction and loyaltyWhat is Included in Mobile Accessories Inspection?The mobile accessories inspection process involves examining various aspects of the product, including:Physical inspection to ensure the accessories are free of damages, scratches, and cracksFunctionality inspection to verify that all features operate optimallySafety inspection to check that the product has passed all the required safety standardsPackaging inspection to ensure that the product is properly labeled and packagedQuantity inspection to ensure that the products match the order and packagingWho Conducts Mobile Accessories Inspection?Mobile accessories inspection is usually conducted by quality control professionals who are qualified and trained in carrying out product inspections. These professionals conduct the inspection process in compliance with the given regulatory standards to ensure product quality and compliance.What are the Challenges Faced in Mobile Accessories Inspection?The mobile accessories inspection process can be challenging because of various factors, including:The high volume of products that need inspectionThe complexity of inspection processes for different productsThe potential of counterfeit and illegal products in the marketThe need for compliance with various regulatory standardsWhat are the Standards to Consider in Mobile Accessories Inspection?Mobile accessories inspection standards are set by regulatory bodies, manufacturers, and industry associations. The standards are meant to ensure that the products are of quality, safe and adhere to regulatory requirements. Some of these standards include the International Organization for Standardization (ISO) standards, China Compliance Inspection (CCC) mark, and the United States Federal Trade Commission (FTC) requirements.ConclusionIn conclusion, mobile accessories inspection is a vital process essential in ensuring quality, reliability, and safety of products. The inspection process involves various procedures that must adhere to regulatory standards. Consumers need to be confident in the quality of the products they purchase and use while also protecting public health and the environment.Quote InquiryIf you have any questions, please let us know asap!